Redundant safety unit enhances wind turbine protection

The challenge: Modern safety standards for older wind turbines

Older wind turbines are still critical to renewable energy generation but often operate on outdated systems. These legacy systems can struggle to meet modern safety and performance standards, particularly when it comes to preventing overspeed events and maintaining reliable operation in harsh environments.

Overspeed - a condition where turbine blades rotate faster than their design limits - can lead to severe damage, including mechanical failure and generator breakdowns. To prevent such risks, precise monitoring and redundant safety measures are essential. However, retrofitting older systems with advanced safety solutions can pose integration and operational challenges.

The solution: PR electronics 4225A – A flexible, redundant safety unit

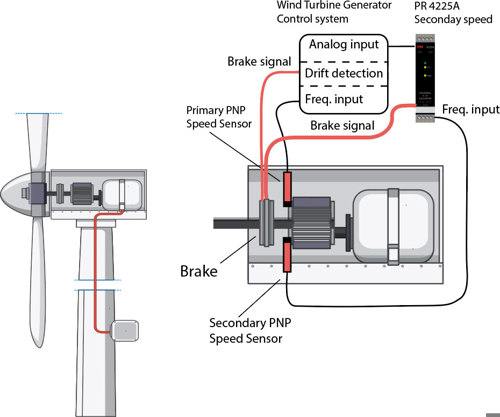

PR electronics’ 4225A provides a robust solution for enhancing safety in wind turbine control systems. This device integrates seamlessly into existing systems and operates independently as a redundant safety unit.

Key features of PR electronics 4225A:

- Redundant monitoring: Equipped with a PNP input, the 4225A monitors rotor speed to detect overspeed events. If the rotor exceeds 120% of the rated speed, the device triggers a safety shutdown via a relay, safeguarding the turbine.

- Standalone functionality: Operates independently from the main turbine controller, ensuring an additional layer of safety in case of main system failure.

- Programmable and user-friendly: The 4225A is configurable through detachable displays (4510 / 4512) and supports local and convenient programming via the PPS app.

- Safety system qualification: The 4225A provides the required failure data (SFF and PFDAVG) for SIL 2 applications as per IEC 61508 / IEC 61511.

Real-world application: Safety in action

A machine builder specializing in control systems for older wind turbines successfully integrated the 4225A into its retrofit designs. By using the 4225A to monitor rotor speed and detect input drift, the company ensured its turbines met modern safety requirements while maintaining optimal performance.

A machine builder specializing in control systems for older wind turbines successfully integrated the 4225A into its retrofit designs. By using the 4225A to monitor rotor speed and detect input drift, the company ensured its turbines met modern safety requirements while maintaining optimal performance.

In practice, the 4225A prevents overspeed and sensor drift by:

- Measuring rotor speed through the PNP input.

- Triggering a safety relay if the speed exceeds a predefined threshold (e.g., 120% of rated speed).

- Providing secondary speed signal to main controller to detect sensor drift, comparing speed readings from system A and B.

This redundancy protects the turbine and significantly reduces the probability of a catastrophic failure event.

Streamlined maintenance and remote access

To enhance serviceability, the 4225A is paired with the detachable displays 4510 and 4512:

- 4510 Display: Provides on-site access for quick readings and configurations.

- 4512 Bluetooth display: Enables convenient handheld configuration and monitoring via the PPS app. Service technicians can access configuration files stored in a cloud folder maintained by the machine builder, ensuring consistent and efficient service across all units.

Benefits of the 4225A for wind turbine safety

- Enhanced safety: Independent operation adds a critical safety layer, reducing the risk of overspeed-related failures.

- Seamless integration: Compatible with older systems, enabling cost-effective retrofits without extensive modifications.

- Proactive maintenance: Drift detection and alarm features enable technicians to identify and resolve issues before they escalate.

- Ease of use: Detachable displays and cloud-based configuration simplify setup, monitoring, and troubleshooting.

- Durability: Built to withstand harsh environmental conditions common in wind turbine applications.

Why Choose PR electronics?

PR electronics has a long-standing reputation for delivering reliable and precise solutions tailored to industrial challenges. With the 4225A, operators of older wind turbines can confidently meet modern safety standards while maximizing the lifespan of their equipment.

Conclusion

Safety and efficiency are paramount in wind turbine operations, and the PR electronics 4225A addresses these needs with precision, reliability, and user-friendly features. Whether you’re retrofitting older turbines or enhancing an existing control system, the 4225A offers peace of mind with its robust and verified safety design.

Ready to upgrade your turbine safety?

Contact us today to learn how PR electronics can help your operations achieve new safety and performance standards.