Oil & Gas

Despite the growing emphasis on renewable energy sources, the oil and gas industry remains a cornerstone of the global economy, playing a crucial role in powering industries, transportation, and communities worldwide.

As oil and gas continue to provide the majority of the world’s energy, fueling everything from power generation to manufacturing, it’s crucial to make the most of our resources and optimize operations wherever we can.

That’s where PR electronics comes into the picture. We know the demands of the oil and gas industry and specialize in designing and producing high-quality signal conditioning solutions tailored to help optimize your systems' efficiency, accuracy, and reliability - even in the most challenging environments. With exceptional performance, durability, and precision, we want to help you drive your business forward.

Discover how PR signal conditioning equipment supports operations in a range of different oil and gas applications.

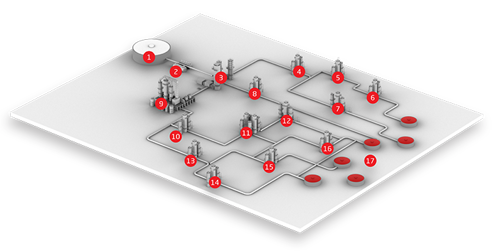

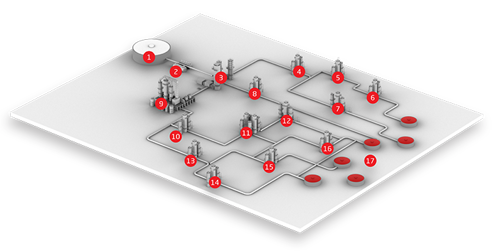

Optimize your refinery process

Below are suggestions for where to use PR electronics products for optimization in an oil refinery plant.

|

Examples - devices used in oil and gas industry

|

-

Drill cabin controls - BOP, Choke and Fire & Gas - 9106B, 9107B & 9202B.

-

Temperature application with demand for Zone 2 & SIL 2 requirements - 9113B.

-

Drilling; control of double-coil hydraulic valve - 2224.

The above are merely examples - please contact us if you require assistance in finding the right device.

|

Customer statement

“At Bebco Industries, we have been using the PR electronics 5202B Pulse Isolators on our Hazardous Area Air Conditioning products for several years. We like the input power flexibility (AC or DC), extreme reliability in harsh environments and cost effectiveness. We would highly recommend PR products”.

James Pagel, Manufacture Engineer, Bebco Industries

|