Enhancing cathodic protection with PR electronics: Precision and reliability for corrosion control

What is cathodic protection?

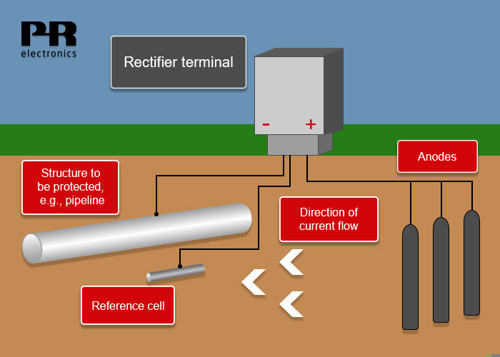

Cathodic protection (CP) is a proven technique for preventing metal corrosion in critical structures such as pipelines, storage tanks, offshore platforms, and marine vessels. It redirects the natural corrosion process by applying an electrical current (in impressed current cathodic protection, ICCP) or sacrificial anodes (in galvanic systems).

By controlling corrosion, industries avoid costly maintenance, extend asset lifespans, and ensure operational safety.

Continuous monitoring and precise adjustment of electrical parameters are essential for CP systems to work effectively. PR electronics provides critical support with advanced signal conditioning and monitoring solutions.

How cathodic protection systems work

Cathodic protection neutralizes the electrochemical reactions that cause metal corrosion.

Impressed current cathodic protection (ICCP):

- Uses an external power source to apply a controlled current to the metal structure.

- Requires accurate monitoring of rectifier output (voltage and current) to ensure optimal performance.

Challenges in cathodic protection systems

Effective CP systems face several challenges:

- Signal integrity: Monitoring current density and potential differences requires high precision to avoid under- or over-protection, both of which can lead to structural failure or resource wastage.

- Environmental conditions: Harsh environments (e.g., high salinity, and extreme temperatures) can disrupt equipment performance.

- Reliability: Systems often operate in remote or inaccessible locations, demanding durable, low-maintenance components.

PR electronics’ role in enhancing cathodic protection

PR electronics doesn’t create complete cathodic protection systems but provides essential components that elevate their efficiency and reliability. Here’s how:

Accurate signal conditioning and monitoring

PR 4114 Universal transmitter:

- Very high input resistance ensures no load on the measurement loop.

- Converts and isolates signals for precise monitoring of voltage.

- Features a high degree of accuracy and fast response times, critical for adjusting ICCP rectifier output in real-time.

- Supports 4-20 mA output, as well as Modbus communication, enabling seamless integration into existing SCADA systems.

Signal isolators and converters:

- Provide reliable isolation of sensitive electrical signals, preventing interference and ensuring data integrity.

PR 4179 Universal transmitter:

- Enhances safety by protecting control systems from stray currents from “noisy neighbors”, like high-voltage cables.

Durability in harsh conditions

- PR electronics’ devices are built for extreme environments, with a long-lasting component lifespan, they can withstand wide temperature fluctuations.

Real-time monitoring and control

- Continuous, accurate measurements ensure CP systems operate at optimal efficiency, minimizing downtime and reducing operational costs.

Practical applications of PR electronics in CP systems

- Transformer / rectifier terminal monitoring:

PR electronics ensures accurate voltage and current readings, allowing ICCP systems to maintain the delicate balance between under and over-protection. - Remote monitoring:

Offshore platforms, buried pipelines, and underground storage tanks rely on PR electronics for precise data transmission, even in remote or hazardous locations.

How PR electronics optimize cathodic protection

Using PR electronics in CP systems delivers the following benefits:

- Improved asset protection: Prevents overcorrection, reducing stress on materials and extending their lifespan.

- Enhanced efficiency: Real-time adjustments minimize energy consumption and system wear.

- Cost savings: Durable, reliable equipment reduces maintenance costs and prevents downtime.

- Regulatory confidence: Helps ensure compliance with international CP standards, avoiding fines and operational disruptions.

Conclusion

Cathodic protection is essential for protecting infrastructure in corrosive environments, and PR electronics play a vital role in enhancing the reliability and efficiency of these systems.

With precision signal conditioning, robust monitoring, and exceptional durability, PR electronics empowers industries to safeguard their critical assets confidently and cost-effectively.

Contact us to learn how PR electronics can elevate your cathodic protection system.