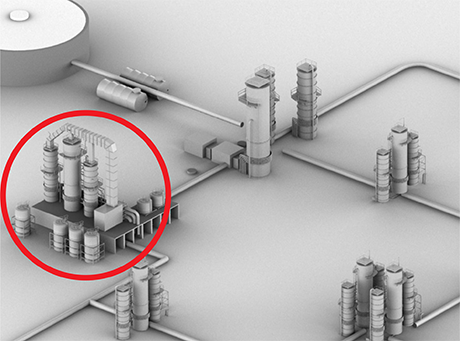

Vacuum distillation

Valve control

As the name vacuum distillation (also referred to as “low temperature distillation”) implies, the distillation column is under a vacuum, or significantly less than an atmospheric pressure of 760 millimeters of mercury (mmHg). At low pressures, the boiling point of the ADU bottoms is low enough that lighter products can vaporize without cracking, or degrading, the oil. Vacuum distillation produces several types of gas oil. In the next stage of refining, these gas oils are further refined to make products such as light-cycle oil (a type of distillate), gasoline and naphtha.

The vacuum column uses a series of pumps around the column to maintain temperature at the correct level at certain points along the tower to achieve the highest yield. The pumps are controlled by solenoid valves to prevent water waste when the pump motor is not working.

To drive the solenoids, the PR 9203B solenoid / alarm driver is a great choice. The 9203B contains three built-in I.S. barriers, which makes it suitable for use with several coil types. Configuration and monitoring of the 9203 is done via the detachable display front (PR 4510) where it is also possible to select direct or inverted function.

Application:

> Need more information? Please contact us.