Beyond the ordinary - Why the PR 5437 transmitter may save your day

We all recognize when a product has that one feature that makes it stand out. Why hasn’t anyone thought of this before? It’s a small difference that not only sets it apart but makes life as a process engineer a bit more efficient and a lot less stressful.

The PR 5437, a 2-wire HART 7 temperature transmitter, offers outstanding accuracy, sensor redundancy, and smart features, making it invaluable for the busy maintenance engineer.

It’s yet another example of PR electronics combining high performance with user-friendly features - what we call:

PERFORMANCE MADE SMARTER

Let’s highlight a few of the smart features of the PR 5437

LED for initial diagnostics

The multicolored LED indicates if the transmitter is working as intended or, if not, signals whether the issue is a process or system error. Here’s what the LED indicator means:

Error messages according to NAMUR NE44 and NE107:

- Flashes red for wire breaks, sensor short circuits, or wiring and configuration mismatches.

- Lights up red for a system error.

- Lights up green when everything is functioning properly.

- Lights up to show that the transmitter is receiving power.

Why is this helpful?

Imagine you’re connecting a Pt100 sensor with poor wiring, where only 3 out of 4 conductors are connected. Without the LED indicator, it's not immediately clear if the wiring is done correctly, making troubleshooting time-consuming.

The LED serves as a valuable support during commissioning or maintenance tasks.

Measure the actual loop current, effortlessly

Often, it’s necessary to tap in and measure the 4-20 mA loop current that represents the measured process temperature.

Often, it’s necessary to tap in and measure the 4-20 mA loop current that represents the measured process temperature.

This involves unscrewing one of the loop wires and inserting a multimeter, which, unfortunately, interrupts your process measurements.

With PR 5437, we’ve introduced a test point that allows you to measure the loop current seamlessly without interrupting the process or involving the operator on duty.

Advanced sensor diagnostics and true dual-sensor support

One of the most common issues with temperature measurements is sensor drift, often caused by the aging of the sensor element or transmitter electronics.

One of the most common issues with temperature measurements is sensor drift, often caused by the aging of the sensor element or transmitter electronics.

The need for recalibration or sensor replacement is time-consuming and results in unwanted production downtime.

Whether it’s thermocouple- or RTD-based, the PR 5437 offers industry-leading solutions to extend maintenance intervals. With dual-sensor element support, you can monitor:

Sensor drift

- Redundancy - if one sensor fails or shorts, the other automatically takes over.

- Through advanced diagnostics via HART 7, you can monitor the transmitter's status:

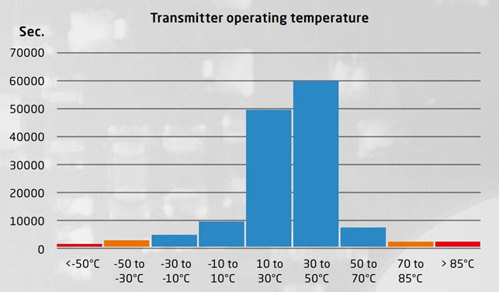

- Runtime meter indicating how many hours the process value or operational temperature has remained within a specific range.

- Status of primary and secondary sensor elements.

Why is this beneficial?

Access to detailed sensor element data enables predictive maintenance, extending intervals between service tasks.

Unexpected sensor failures impacting your process are significantly reduced thanks to sensor redundancy, and reliable detection of sensor drift occurs early on.

All of this helps reduce maintenance costs and, most importantly, minimizes production losses due to unforeseen disruptions.

PRODUCT FAQ: PR 5437

The PR 5437 HART transmitter advances the state-of-the-art in head-mounted HART transmitters.

Question:

- Can the PR 5437 be used in applications exposed to extreme variations in environmental conditions?

Answer:

- The transmitter operates over a wide -50…+85°C ambient temperature range and is rated IP68 (submersible).

Question:

- What HART communication protocols can be used with the PR 5437?

Answer:

- The user can configure the PR 5437 to communicate using either the HART 7 or HART 5 communication protocol.

This flexibility means that the PR 5437 is usable in today’s HART 5 systems and ready for tomorrow's HART 7 systems – without having to replace the transmitter.

Question:

- How can loop current in the PR 5437 be measured?

Answer:

- The PR 5437 has innovative loop test points that let you measure the loop current - without opening the loop or disturbing the transmitter.

Question:

- What do the jumpers on the PR 5437 do?

Answer:

- Jumpers on the PR 5437 enable transmitter write protection and define the current value during sensor error. For extra security, the jumpers control these functions – regardless of module configuration.

Question:

- What is the purpose of the built-in LED?

Answer:

- The PR 5437 is the first PR head-mounted transmitter with a built-in LED. This LED provides visual notification of sensor, transmitter, and loop status.

Question:

- Which sensors can be measured with the PR 5437?

Answer:

- The PR 5437 provides the widest selection of dual-sensor input combinations on the market. Virtually any thermocouple or RTD found in the world can be measured, plus linear resistance up to 100 kΩ, potentiometer, and bipolar mV signals.

You can match the PR 5437 to your sensor using multipoint linearization, polynomial linearization, or by simply entering the Callendar van Dusen coefficients of your sensor.

Question:

- Why does the PR 5437 have built-in “runtime meters” – and what are they?

Answer:

- One meter records sensor temperature and the other records the transmitter's internal operating temperature.

The runtime meters provide a valuable history of the process temperature and the ambient temperature around the transmitter.

Question:

- Does the PR 5437 comply with NAMUR standards?

Answer:

- The PR 5437 is in compliance with several NAMUR standards, meeting the EN 61326-3-1 EMC requirement and exceeding the NAMUR NE21 burst immunity test. This excellent performance helps ensure that the transmitter will continue to operate reliably, even in areas with high levels of electromagnetic interference.

Compliance with NAMUR NE43 and NE89 means that the PR 5437 is compatible with a wide range of HART analog input devices. The PR 5437 also fully supports the NAMUR NE107 standard.

The transmitter provides status bits, including diagnostic data to master devices running EDDL device management software. These status bits make it easy for the PR 5437 to communicate a range of sensor and transmitter faults to the customer’s control system.

Question:

- Why are there two versions of the PR 5437?

Answer:

- The PR 5437 is also available in a dual input version, the PR 5437_2: It looks different than any other head-mounted transmitter on the market and has many advanced features.

The transmitter has 7 input terminals, and it measures one or two sensors – including two 4-wire RTDs with individual sensor error detection.

Question:

- What does the PR 5437_2’s sensor redundancy function do?

Answer:

- If sensor A fails, the transmitter immediately switches to sensor B and sends a HART error message. Sensor redundancy is also available when measuring the average, difference, minimum or maximum of two sensors.

The sensor redundancy function is used in critical process measurements, where notification of a bad sensor – with automatic switchover to the good sensor – is essential for process reliability.

Question:

- Can the PR 5437_2 also detect sensor drift?

Answer:

- Yes. If either sensor drifts beyond a configured amount compared to the other sensor, the mA output goes to the sensor error value, and a HART alarm occurs.

The sensor drift function is often used when two sensors measure the same process temperature. In critical applications, it is important to know if one of the sensors is beginning to drift.

Question:

- What approvals does the PR 5437 have?

Answer:

- The PR 5437 has a wide range of I.S. and safety approvals, plus the transmitter is available with a full SIL2/SIL3 functional safety assessment and marine approval.