Temperature / mA converter, EMPHASIS assessed

9113A-EMP

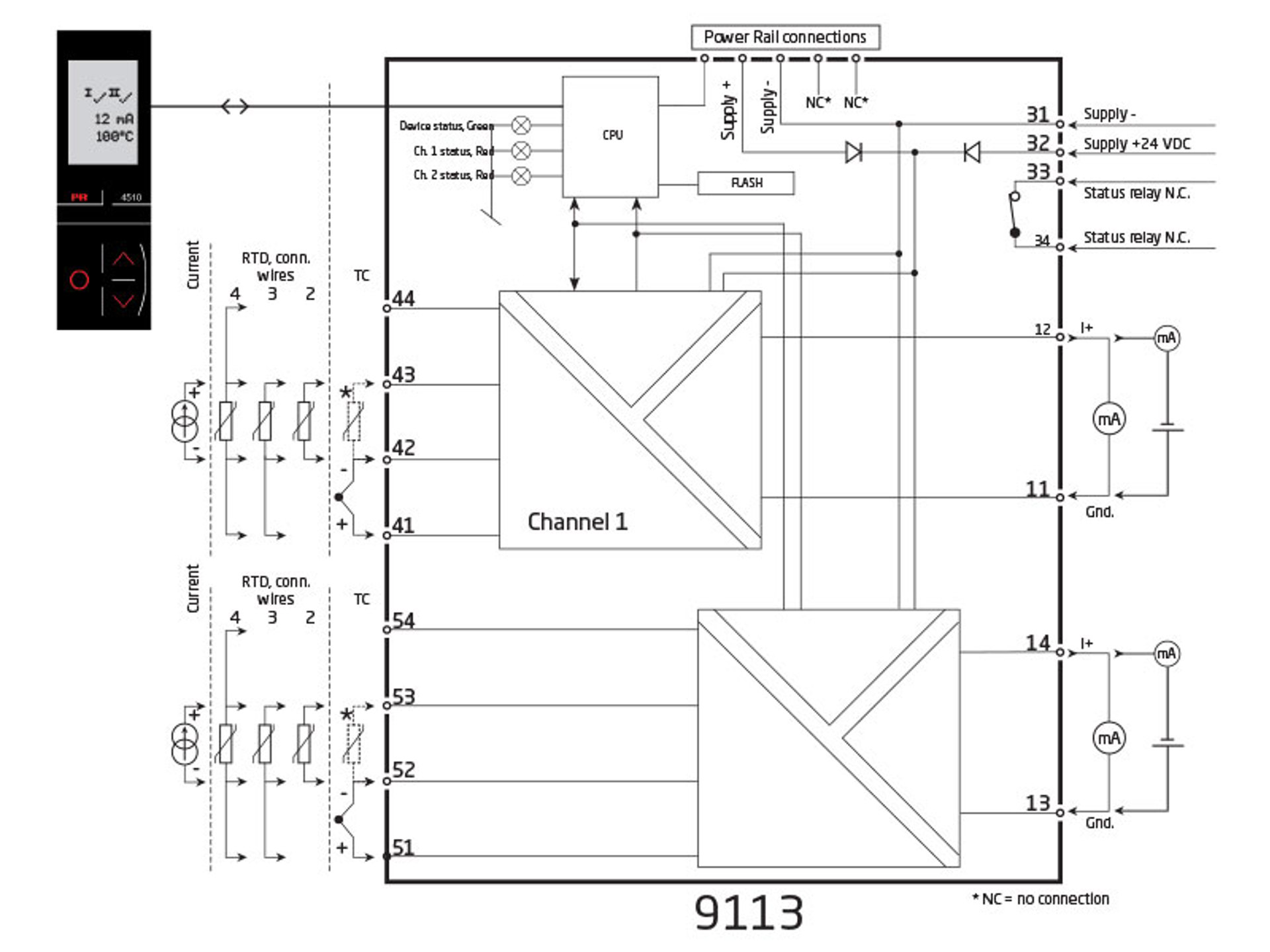

- Input for RTD, TC and mA

- Active / passive mA output via the same two terminals

- 1 or 2 channels

- EMPHASIS assessed instrument for nuclear industry

- SIL 2-certified via Full Assessment

Advanced features

- Configuration and monitoring by way of detachable display front (PR 4500); process calibration and signal simulation.

- Copying of the configuration from one device to others of the same type via the display front.

- TC inputs can use either the internal CJC or a terminal with a built-in Pt100 sensor (PR 5910, channel 1 / PR 5913, channel 2) for higher accuracy.

- Advanced monitoring of internal communication and stored data.

- SIL 2 functionality is optional and must be activated in a menu point.

Application

- 9113A-EMP can be mounted in the safe area or in zone 2 / Class I, Division 2, Groups A, B, C, D.

- Conversion and scaling of temperature (Pt, Ni and TC) and active current signals.

- 9113A-EMP has been designed, developed and certified for use in SIL 2 applications according to the requirements of IEC 61508.

- Suitable for the use in systems up to Performance Level “d” according to ISO-13849.

Technical characteristics

- 1 green and 2 red front LEDs indicate operation status and malfunction.

- 2.6 kVAC galvanic isolation between input, output and supply.

- Can be supplied separately or installed on power rail, PR type 9400.

Mounting

- The devices can be mounted vertically or horizontally without distance between neighbouring units.

Data sheet & Manuals

Data sheet

- 9113A-EMP.pdf

- Latest version

Manuals

- 9113EMPV004_112_UK.pdf

- 9113EMPV004_111_UK.pdf

- 9113EMPV004_110_UK.pdf

- 9113EMPV004_109_UK.pdf

- 9113BEMPV004_108_UK.pdf

- 9113BEMPV004_107_UK.pdf

- 9113AEMPV004_102_UK.pdf

- Previous versions

- Latest version

Manuals in Russian

- 9113EMPV004_112_RU.pdf

- 9113EMPV004_111_RU.pdf

- 9113EMPV004_110_RU.pdf

- 9113EMPV004_109_RU.pdf

- 9113BEMPV004_108_RU.pdf

- 9113BEMPV004_107_RU.pdf

- Previous versions

- Latest version

Manuals in Portuguese (Brazil)

- 9113EMPV004_112_BR.pdf

- 9113EMPV004_111_BR.pdf

- 9113EMPV004_110_BR.pdf

- 9113EMPV004_109_BR.pdf

- 9113BEMPV004_108_BR.pdf

- 9113BEMPV004_107_BR.pdf

- Previous versions

- Latest version

Safety manual (SIL)

- 9113_Safety_Manual_V9R0.pdf

- Latest version

Approvals & Certificates

ATEX certificate

- 9113A_07ATEX0148X_issue5.pdf

- 9113A_07ATEX0148X_issue4.pdf

- 9113A_014ATEX0101X_issue2.pdf

- 9113A_014ATEX0101X_issue1.pdf

- Previous versions

- Latest version

IECEx certificate

- 9113AIEC_090052x_issue4.pdf

- 9113AIEC_090052x_issue3.pdf

- Previous versions

- Latest version

UKEX certificate

- 9113A_21UKEX0175X_issue0.pdf

- Latest version

FM certificate

- 9113_FM19US0059X_FM19CA0032X.pdf

- Latest version

INMETRO certificate

- 9113_INMETRO_230005X_issue0.pdf

- Latest version

SIL certificate

- 9113_004_SIL.pdf

- Latest version

UL certificate

- 9113_UL.pdf

- Latest version

CCC certificate

- 9113_CCC_2024_03.pdf

- Latest version

DNV marine certificate

- DNV_9xxx_4510_4511.pdf

- 9000_DoC_DNV.pdf

- Previous versions

- Latest version

ClassNK certificate

- ClassNK-TA24034M_91xx_92xx_94xx.pdf

- Latest version

EAC declaration

- EAC_EMC_declaration_Ex_3000_5000_6000_9000.pdf

- Latest version

EAC LVD declaration

- EAC_LVD-Declaration.pdf

- Latest version

EAC Ex certificate

- EAC_Ex.pdf

- Latest version

Metrology Pattern Approval (MPA), Russia

- MPA_Russia.pdf

- Latest version

Supplementary documentation

EU Declaration of Conformity

- 9113DoC_EU_103_UK.pdf

- 9113DoC_EU_102_UK.pdf

- 9113DoC_EU_101_UK.pdf

- 9113DoC_EU_100_UK.pdf

- Previous versions

- Latest version

UKCA Declaration of Conformity

- 9113DoC_UKCA_100.pdf

- Latest version

Modbus configuration manual

- 9113_MCM_101.pdf

- Latest version

Assessment report

- AssessmentReport_PR_2312098_V1R0_Series_9000.pdf

- Latest version

FMEDA report

- PR_060319_R022_FMEDA_9113_V3R3.pdf

- Latest version

EMC data

- 9000_EMC_data.pdf

- Latest version

Safety note

Safety note

- SN9113-113-2436.pdf

- SN9113-112-2411.pdf

- SN9113-111-2306.pdf

- SN9113-110-2007.pdf

- SN9113-109-1907.pdf

- SN9113-108-1749.pdf

- Previous versions

- Latest version

Order form

Environmental Conditions

| Operating temperature | -20°C to +60°C |

| Storage temperature | -20°C to +85°C |

| Calibration temperature | 20...28°C |

| Relative humidity | < 95% RH (non-cond.) |

| Protection degree | IP20 |

| Installation in | Pollution degree 2 & meas. / overvoltage cat. II |

Mechanical specifications

| Dimensions (HxWxD) | 109 x 23.5 x 104 mm |

| Dimensions (HxWxD) w/ PR 4500 | 109 x 23.5 x 131 mm |

| Weight approx. | 250 g |

| DIN rail type | DIN EN 60715/35 mm |

| Wire size | 0.13...2.08 mm2 AWG 26...14 stranded wire |

| Stripping length | 5 mm |

| Screw terminal torque | 0.5 Nm |

| Vibration | IEC 60068-2-6 |

| 2...13.2 Hz | ±1 mm |

| 13.2...100 Hz | ±0.7 g |

Common specifications

Supply |

|

| Supply voltage | 19.2...31.2 VDC |

| Max. required power | ≤ 0.8 W/≤ 1.4 W (1 ch./2 ch.) |

| Max. power dissipation, 1 / 2 ch. | ≤ 0.8 W / ≤ 1.4 W |

| Fuse | 400 mA SB / 250 VAC |

Isolation voltage |

|

| Test /working: Input to any | 2.6 kVAC / 300 VAC reinforced isolation |

| Analog output to supply | 2.6 kVAC / 300 VAC reinforced isolation |

| Status relay to supply | 1.5 kVAC / 150 VAC reinforced isolation |

Response time |

|

| Temperature input, programmable (0...90%, 100...10%) | 1...60 s |

| mA / V input (programmable) | 0.4...60 s |

| Programming | PR 4500 communication interfaces |

| Signal / noise ratio | Min. 60 dB (0...100 kHz) |

| Signal dynamics, input | 24 bit |

| Signal dynamics, output | 16 bit |

| Accuracy | Better than 0.1% of sel. range |

| EMC immunity influence | < ±0.5% of span |

| Extended EMC immunity: NAMUR NE21, A criterion, burst | < ±1% of span |

Input specifications

RTD input |

|

| RTD type | Pt10/20/50/100/200/250; Pt300/Pt400/500/1000; Ni50/100/120/1000 |

| Cable resistance per wire | 50 Ω (max.) |

| Sensor current | Nom. 0.2 mA |

| Effect of sensor cable resistance (3-/4-wire) | < 0.002 Ω / Ω |

| Sensor error detection | Programmable ON / OFF |

TC input |

|

| Thermocouple type | B, E, J, K, L, N, R, S, T, U, W3, W5, LR |

| Cold junction compensation (CJC) via ext. sensor in 5910 | 20...28°C ≤ ±1°C, -20...20°C / 28...70°C ≤ 2°C |

| CJC via int. mounted sensor | ±(2.0°C + 0.4°C * Δt) |

| Sensor error detection | Programmable ON or OFF (only wire breakage) |

| Sensor error current: When detecting / else | Nom. 2 μA / 0 μA |

Current input |

|

| Measurement range | 0...23 mA |

| Programmable measurement ranges | 0...20 and 4...20 mA |

| Input resistance | Nom. 20 Ω + PTC 50 Ω |

| Sensor error detection | Programmable ON / OFF |

Output specifications

Current output |

|

| Signal range | 0...23 mA |

| Programmable signal ranges | 0...20/4...20/20...0/20...4 mA |

| Load (@ current output) | ≤ 600 Ω |

| Load stability | ≤ 0.01% of span / 100 Ω |

| Sensor error indication | 0 / 3.5 / 23 mA / none |

| NAMUR NE43 Upscale/Downscale | 23 mA / 3.5 mA |

| Output limitation, on 4...20 and 20...4 mA signals | 3.8...20.5 mA |

| Output limitation, on 0...20 and 20...0 mA signals | 0...20.5 mA |

| Current limit | ≤ 28 mA |

Passive 2-wire mA output |

|

| Max. external 2-wire supply | 26 VDC |

| Effect of external 2-wire supply voltage variation | < 0.005% of span / V |

Status relay |

|

| Max. voltage | 125 VAC / 110 VDC |

| Max. current | 0.5 AAC / 0.3 ADC |

| Max. AC power | 62.5 VA / 32 W |

| of span | = of the presently selected range |

Observed authority requirements

| EMC | 2014/30/EU & UK SI 2016/1091 |

| LVD | 2014/35/EU & UK SI 2016/1101 |

| ATEX | 2014/34/EU & UK SI 2016/1107 |

| RoHS | 2011/65/EU & UK SI 2012/3032 |

| EAC | TR-CU 020/2011 |

| EAC LVD | TR-CU 004/2011 |

| EAC Ex | TR-CU 012/2011 |

Approvals

| ATEX | KEMA 07ATEX0148 X |

| IECEx | KEM 09.0052X |

| UKEX | DEKRA 21UKEX0175X |

| c FM us | FM19US0059X / FM19CA0032X |

| INMETRO | DEKRA 23.0005X |

| c UL us, UL 61010-1 | E314307 |

| CCC | |

| EAC Ex | EAEU KZ 7500361.01.01.08756 |

| DNV Marine | TAA00000JD |

| ClassNK | TA24034M |

| SIL | SIL 2 certified & fully assessed acc. to IEC 61508 |

Need support to select the right product for your application?

Our sales engineers are ready to help specify the right device to meet your needs.

Reach out by phone to get in touch with us straight away – or use the contact form or quick quote function to send your RFQ directly from the website. You’ll get a response within 24 hours on normal business days.

You can expect to get a confirmed delivery date via email within 2 days after we have received your order.

As soon as your package leaves our warehouse, you’ll receive tracking details via email. And if you have any questions along the way we’re just a phone call or email away.

|

State-of-the-art manufacturing Our 8,500 sqm integrated and automated manufacturing campus in Denmark covers the entire value-chain from design and development to manufacturing. It allows us to design and optimize for testing and manufacturing thereby constantly driving quality up and costs down. |

|

Dedicated Presale / Aftersales

|

|

Product reliability |

|

Product deployment

|

|

Smart products

Check out our range of communication interfaces

|